Water-based graph ink for 3D printing

Image: PxHere

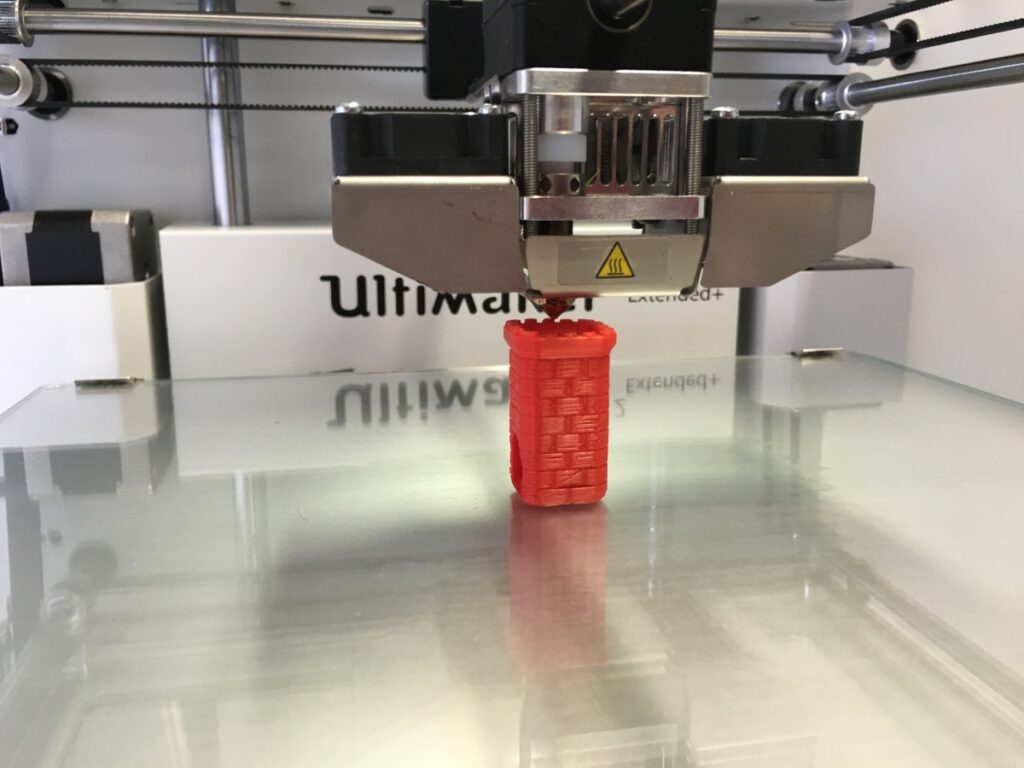

Water-based graph ink for 3D printing– Researchers at the University of Waterloo (Canada) have developed an additive-free, water-based graph ink that offers new possibilities for applications in electronics, the automotive industry and environmental technology. The ink can be processed with 3D printers and offers sustainable solutions for countless technical challenges.

Graphene is considered a promising material due to its unique electrical and thermal properties. However, its industrial application is limited by the difficulty of handling its powdery structure. Researchers at the University of Waterloo have solved this problem by developing a water-based, additive-free graphene ink. This new formulation allows graphene to be molded into complex geometries using 3D printing without the need for chemical solvents. This makes production more environmentally friendly and versatile.

Various applications of graph ink

The high conductivity and malleability of graph ink make it suitable for a range of applications. It can be used in wearable sensors for smartwatches or blood glucose meters for diabetics. In the automotive industry, it can be used to produce lighter vehicle parts, which reduces fuel consumption and increases durability. The ink can also be used in environmental technologies, for example to filter and desalinate water or to clean oil spills with superabsorbent structures. Another promising approach is the capture of carbon dioxide to actively combat climate change.

Options for organic coatings

Water-based graphene ink also opens up new possibilities for organic coatings. It can be used as a conductive layer in functional coatings that are used in flexible electronics or smart surfaces, for example. In addition, the ink enables the development of durable, solvent-free protective coatings for metals and plastics, allowing more environmentally friendly coating processes to be achieved.

Efficient mass production thanks to new process.

Special process

An important aspect of this innovation is the newly developed two-stage electrochemical process that enables the production of graphene nanosheets in water. A special intercalation process, in which molecules are introduced into layered graphite, enables the continuous production of nanoscale graphene particles.

Possible breakthrough in sustainable material development

According to the director of the Multiscale Materials Design Lab at the University of Waterloo, Prof. Milad Kamkar, this technology could be a breakthrough in the development of sustainable materials. The new ink combines environmental friendliness with high performance and paves the way for innovative applications in a wide range of industries.

Reading tip: Silicon and nanotechnology for coatings

Dive into the world of advanced coatings with “Silicon and Nanotechnology for Coatings”. This comprehensive guide explores the interface between nanotechnology and silicone chemistry and offers insights into improving coating performance through innovative materials. Learn more about cutting-edge applications and future trends shaping the coatings industry.

European Coatings Show 2025

The biennial ECS conference will take place from March 25-27, 2025 in Nuremberg, Germany. This event offers everything you need to stay at the forefront of your field. Experts from all over the world come together to present developments, participate in debates and exchange valuable information.

Siam Software is present

Siam Software for Safety Sheets will also be present at ECS 2025 (Hall 3, Stand 3-663). For almost twenty years, Siam has been developing advanced software that enables suppliers of hazardous chemicals to easily create safety data sheets (SDS or MSDS) and labels. Our innovative approach and the excellent support we provide help companies in the chemical industry to meet regulatory requirements.

Constantly evolving software

Thanks to partnerships with leading institutions in the chemical industry, Siam ensures that our software continuously grows with the changing legislation and requirements of chemical manufacturers. Online training keeps our customers informed of new legislation and updates to our software.

Worldwide support

With an international network of representatives, we support customers in more than 50 countries. The growing community of Chemeter users with more than 1,000 satisfied customers worldwide is a testament to our success and commitment to quality.

Meet us at the ECS 2025

Would you like to meet us at the European Coatings Show in Nuremberg (Hall 3, Stand 3-663) or would you like a free, no-obligation demonstration of our software? Send an e-mail to demo@european-coatings-show.eu and let us know which day and time suits you best. We look forward to meeting you!

Source: European Coatings

Also read: Sustainable hybrid coating for the preservation of street art

Reservation

This information has been compiled with the greatest possible care, in some cases from different information sources. (Interpretation) errors are not excluded. No legal obligation can therefore be derived from this text. Everyone dealing with this subject has the responsibility to delve into the matter!